ABOUT VIBRANT

Vibrant Engineering Solutions, a bangalore based AS9100D certified company founded in the year 2012 by a team of experienced engineers, specializes in manufacturing precision CNC machine components for the aerospace, medical and automotive sectors.

Driven by a team of qualified professionals, Vibrant is committed to quality and on-time delivery.

We focus on continuous improvement to shorten the product development cycle, giving us a competitive edge in the industry.

We have received an AS9100D and ISO 9001:2015 certification from TUV SUD. The scope says “Manufacture and Supply of Machined Components for Aerospace, Defence and General Engineering Applications”

VISION and MISSION

VISION

We aspire to become the nation’s premier manufacturer of precision components, serving a diverse array of global engineering sectors. We will collaborate as a unified team, prioritizing strict adherence to quality and on-time delivery to enhance profitability, thereby ensuring the satisfaction and well-being of our customers.

MISSION

To achieve our objectives in an environment of integrity, focusing on:

- Quality

- Growth

- Innovation

- Creating an exceptional workplace environment

HUB OF EXCELLENCE

Skilled & Trained Experts

We hire qualified co-workers and provide in-house training to improve their skillset

Collaborative Working

We encourage all team members to share their ideas which leads to better coordination of organization activities

Streamlined Processes

We have implemented AS9100 to streamline the process and make the organization more efficient

Meet Customer Requirement & Timeline

Shorter timeline with required documentation will be provided to customer

Quality Assurance

We have maintained 100% quality rating for prototype jobs and more than 95% rating with other suppliers

VIBRANT BUSINESS STRATEGY

- Innovation and Digitalization

- Continuous improvement on existing process

- Complex Precision Jobs

- Tough material machining

- Quality Standards

- Diversified Business

- Aerospace – 85%

- Medical – 5%

- Automotive – 5%

- General Engineering – 5%

- High/Low Volume Manufacturing

- Prototype

- Batch Production

- Serial Production

MACHINING AND INSPECTION CAPABILITIES

We maintain the highest standards for our technology and equipment. Our turning and milling processes adhere rigorously to precise positioning and machine accuracies, achieving the following specifications:

- Milling maximum dimensions: X = 1060mm, Y = 600mm, Z = 500mm

- Turning maximum dimensions: X = 300mm, Z = 500mm

- Position accuracy and repeatability: ±5 microns

Vibrant is deeply committed to continually enhancing its products to exceed customer expectations in terms of quality, cost, and delivery. Our maximum part inspection dimensions reflect our dedication:

- X = 1000mm, Y = 700mm, Z = 600mm

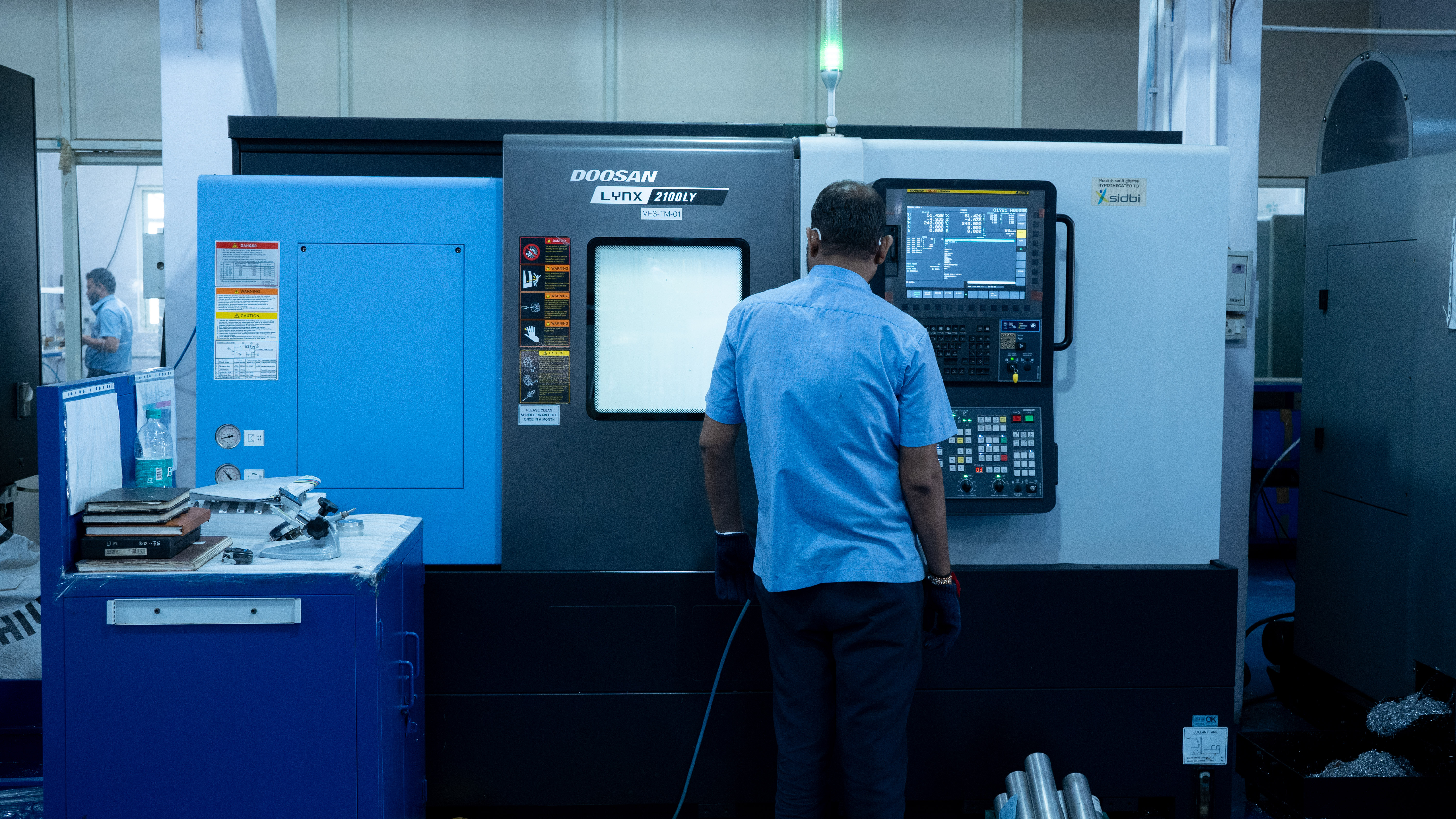

WORKPLACE IMAGERY

EQUIPMENT CAPABILITIES

| 3 Axis VMC | 4 Axis VMC | Simultaneous 5 Axis | Positional 5 Axis |

|---|---|---|---|

| Cosmos 1160 | BFW Agni BMV 45TC24+ | Hurco VC500i | Cosmos 800 |

| Hurco VM10i | Phillips PVM 850 | Hurco Zri | Phillips PVM 1060 |

| Cosmos 800 | Cosmos 800 | Hurco VM10Ui | |

| Maple 850 | Hyundai Wia KF4600II | ||

| 2 Axis | 4 Axis Turn Mill | ||

| Mazak Quickturn Primos 150S | Doosan Lynx 2100LYB | ||

| Tsugami Mi08J-II | |||

| Hyundai E160A | |||

| LMW L5 | |||

| LMW L3 | |||

| LMW Smart turn | CMM | VMS | Surface Roughness | Contour Tracer |

| SPECTRUM II (Carl Zeiss) | ATQ Automatic 400x300x200 | Handysurf (Carl Zeiss) | Contourecord 1600G |

| CONTURA G2 (Carl Zeiss) | Cimtrix Manual YF3020 | ||

Our Clients